From the outer reaches of space to the depths of our planet's oceans, Glenair provides interconnect solutions in the harshest of environments.

Connector backshells and accessories are designed to improve the durability, life, resilience and efficiency of your connectors and cable assemblies.

Our range covers all MIL-C-22520 qualified products including Indent and Open Frame tooling, pneumatic and hand operated, along with MIL-I-81969 insertion and removal tools.

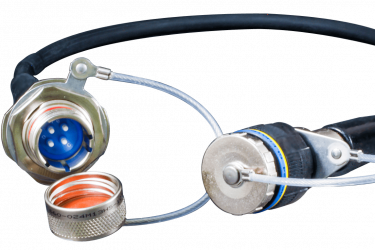

The advantages of a connection system that can transmit the equivalent of 24,000 telephone calls simultaneously through fibres thinner than a human hair — and over longer distances than would ever be possible with copper media — go beyond their mind-boggling data transmission rate.

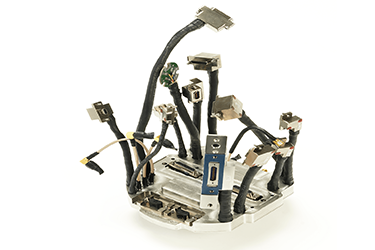

Interconnect Wire Harness and Cable Assemblies are the connectivity backbone of electronic systems. Fabricated in a factory setting, cable harness assemblies enable the OEM manufacturer to reduce the time and expense of in situ interconnection of electronic devices used in complex air, sea, land and space applications.

Integrated Soldier Multiport USB Data Hub / Power Distribution Systems.

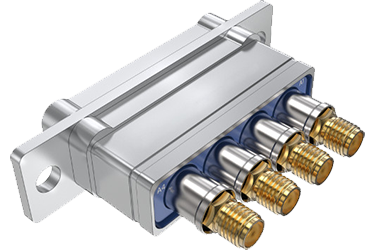

Used in harsh environments where low loss performance is key, Glenair high frequency, high-performance coax connectors, cables, assemblies and accessories can help solve your interconnect challenges.

IECEx/ATEX qualified ITS-Ex connectors for hazardous/explosive areas.

Hermetic connectors are a special class of Mil/Aero interconnect that incorporates glass-to-metal or other highly-engineered sealing technology. Hermetic connectors are specified for applications as divergent as submarines and orbiting satellites.

Glenair: Dedicated to making new and ongoing product development a mainstay of our business.

Glenair has been in the interconnect industry since 1956, plenty has changed over the last 60 plus years, but our commitment to new product development has remaioned constant. We now manufacture thousands of industry-standard and special purpose connector designs, backshells, wire protection and management products, cable harnesses, lightweight EMI/RFI shielding solutions and more. We didn't get to where we are overnight, but a current snapshot of Glenair shows just how far we have come, and just how dedicated we are to making new and ongoing product development a mainstay of our business.

Even a cursory look at our current capabilities reveals just how innovative our product people and engineers have become. From our industry-leading Series 80 Mighty Mouse connector to our brand new and ultra-miniature SuperFly™ cordsets, Glenair has become the go-to market leader for innovation in interconnect systems. While many of our industry peers are seemingly content to rely on existing designs and their long-term print position in high-reliability systems, Glenair has taken steps to gear our outfit with a focus on innovation – tackling the toughest problems around – from size and weight reduction to better solutions for high-speed data transmission.

Literally all our business development work – from the expansion of our engineering and support capabilities to the growth of our factory space and manufacturing resources – have been undertaken with one goal in mind: Responding with as much urgency as we can muster to the needs of our customers. We understand there is no better way to address those needs than to conduct every customer conversation with our ears wide open.

Glenair: Where Connector Manufacturing Meets Cable Harness Assembly

If there is one thing we understand well at Glenair, it’s how to build interconnect assemblies for high-reliability systems. In fact, when it comes to protecting both electrical and optical media from mechanical stress, corrosion damage, lightning strike, physical abuse, nuclear, biological or chemical contamination and more, there is no more experienced cable operation in the business than Glenair. In large part this is due to our extensive interconnect component design and manufacturing capabilities combined with our many years of experience in military grade and harsh environmental commercial cable harness fabrication.